WholeMilkPlus

Modern whole milk feeding for calf feeders – including solutions for storage and cooling as well as the cleaning of all connected equipment and lines.

Flexible whole milk feeding and storage options to suit any farm.

Optimum use of whole milk resources thanks to intelligent control.

Healthy, contented calves thanks to unrestricted access to fresh whole milk.

Intelligent whole milk feeding on the CalfExpert

Whole milk feeding is becoming increasingly important in calf rearing because calves develop very well with natural whole milk. In addition, feeding whole milk from one’s own farm means conserving valuable resources.

However, there are a few technical things to consider when feeding from the calf feeder. The milk must be cooled during storage in the CalfExpert to keep it fresh. Furthermore, the hygiene and cleaning of the storage tanks and the milk line are very important. There has to be a constant supply of milk in the storage tank because the calves come to feed all day long. However, if the calves drink more than usual, the tank will empty too soon and the animals will not be able to obtain any milk for a certain period of time. On the other hand, there are often residual amounts left in the tank when it needs to be cleaned and then refilled. This is then often discarded.

Finally, dairy farms have different operations that require the feeder to be prepared for all whole milk scenarios.

But this is no problem for the CalfExpert. You can learn how it became the best whole milk feeder in the market here.

Feeding high-quality whole milk intelligently

Whole milk is digested perfectly by the calf and results in the best performance. The CalfExpert whole milk program gives you the flexibility to set whole milk percentages or upgrade the whole milk in the feed program.

Flexible whole milk programs

The CalfExpert feed curves not only enable the amount of milk and the concentration of milk replacer to be set, but also allow the proportions of whole milk to be adjusted according to age. This permits a gradual transition from whole milk components, meaning calves can slowly become accustomed to the change in feed.

WholeMilkSmart

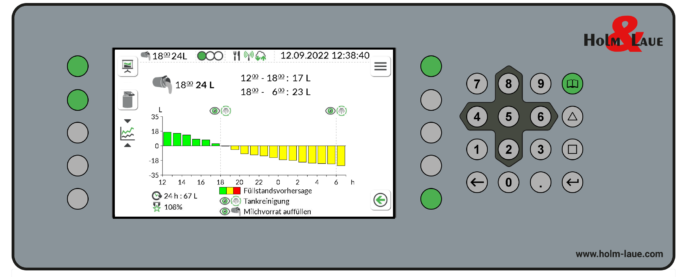

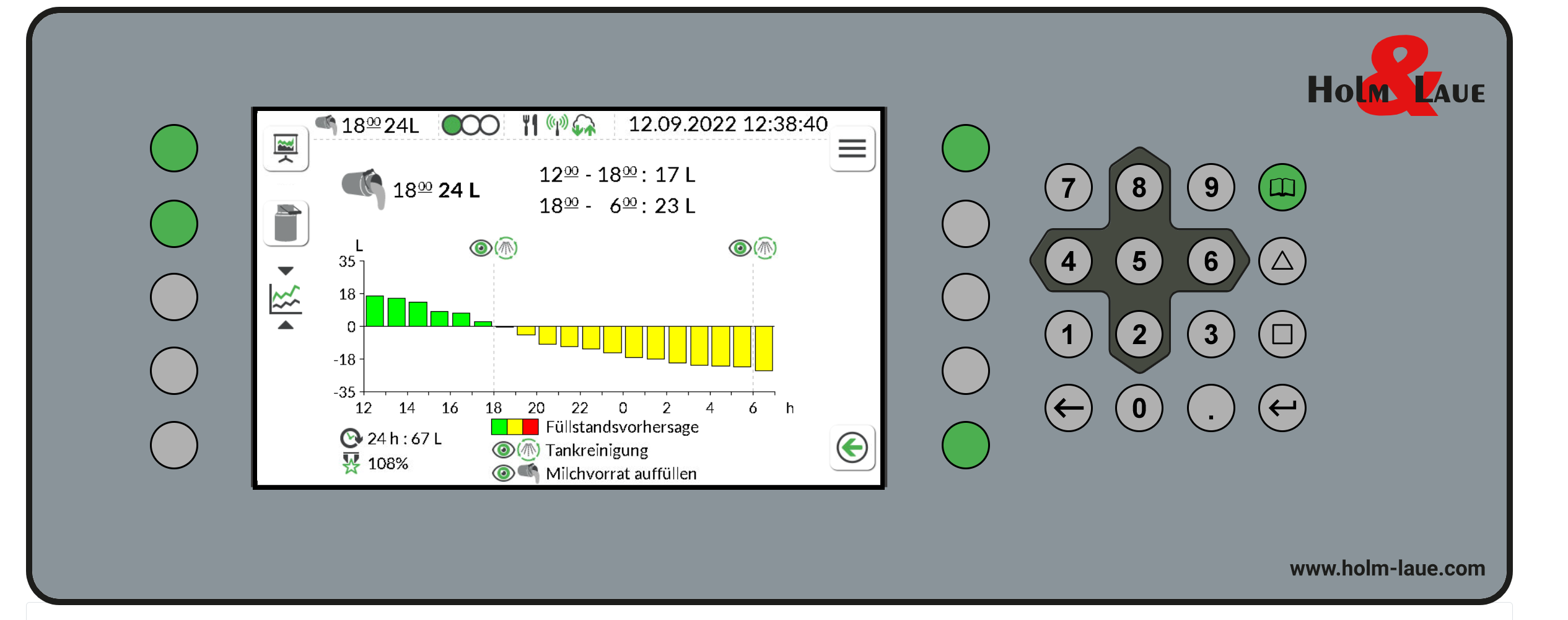

This option on the CalfExpert includes a fill level sensor that can determine the fill level of the connected milk tank based on the pressure in the milk line.

CalfExpert can predict how long the milk supply will last by taking into account the calves' expected consumption. The corresponding menu then shows the minimum amount of milk that needs to be refilled the next time you are in the barn (in the example: at least 24 l at 6:00 pm).

This overview is also available in the CalfExpert without WholeMilkSmart, but the amount of milk must then be entered manually.

EvenMilk: feeding whole milk intelligently

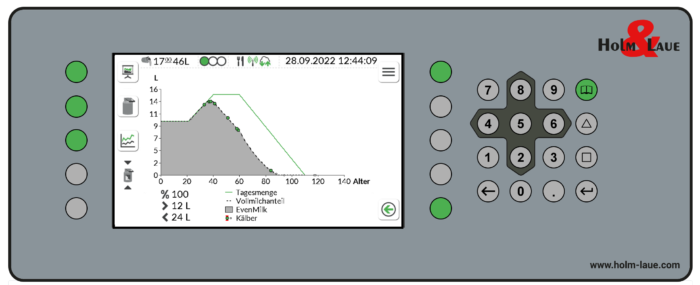

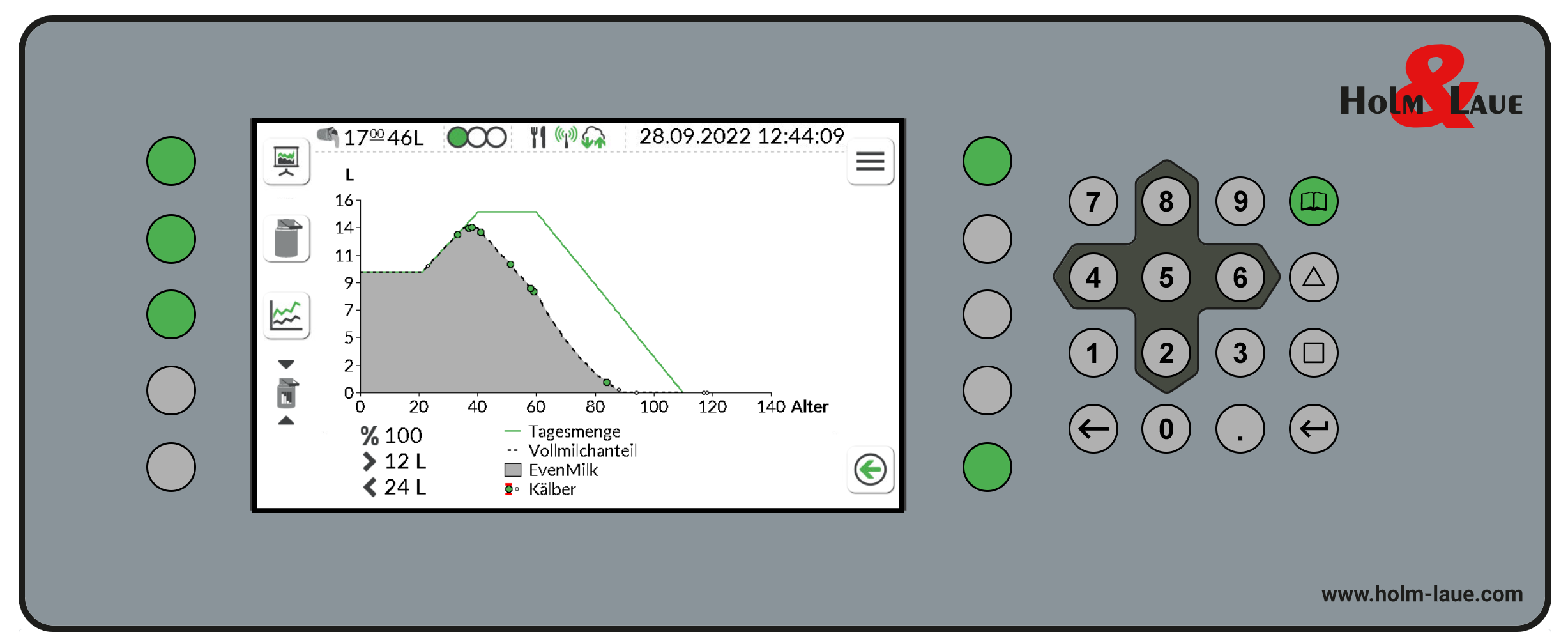

What happens with your calf feeder if the supply of whole milk is insufficient and is used up prematurely? Does it then use powdered milk as a substitute? This causes changeover stress with your calves and is likely to cause digestion problems. The "EvenMilk" option provides information on the amount of milk available and the expected quantity to be consumed to ensure that the missing quantities of whole milk are supplemented evenly using milk replacer feed. A uniform ratio of the two feeds is calculated and fed over the course of the day.

The whole thing is also done while taking into account the different needs of young and older calves. Younger calves, for example, prefer to receive whole milk, while older animals already receive higher proportions of milk replacer.

Storing whole milk in traditional milk tanks

There are different ways of storing and dispensing milk depending on the size of the farm and how work is organised. However, it is always necessary to ensure that the tanks and all milk lines are adequately cleaned. As the CalfExpert feeds 24 hours a day, it is important to avoid long waiting times caused by cleaning. For this reason, there are various solutions on the CalfExpert for different whole milk scenarios.

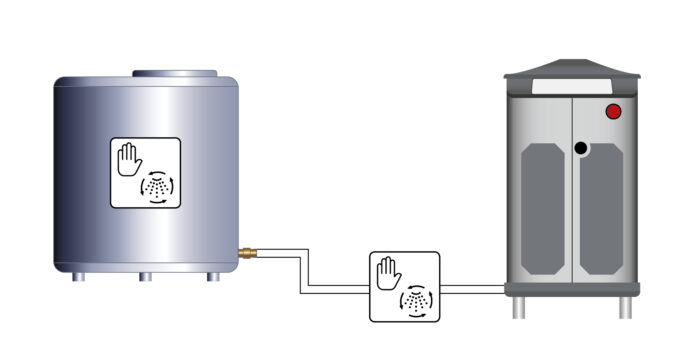

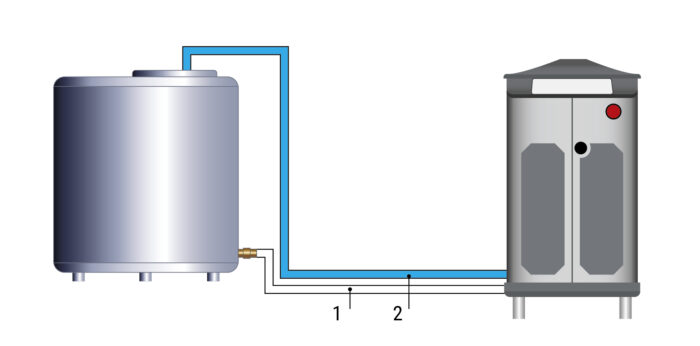

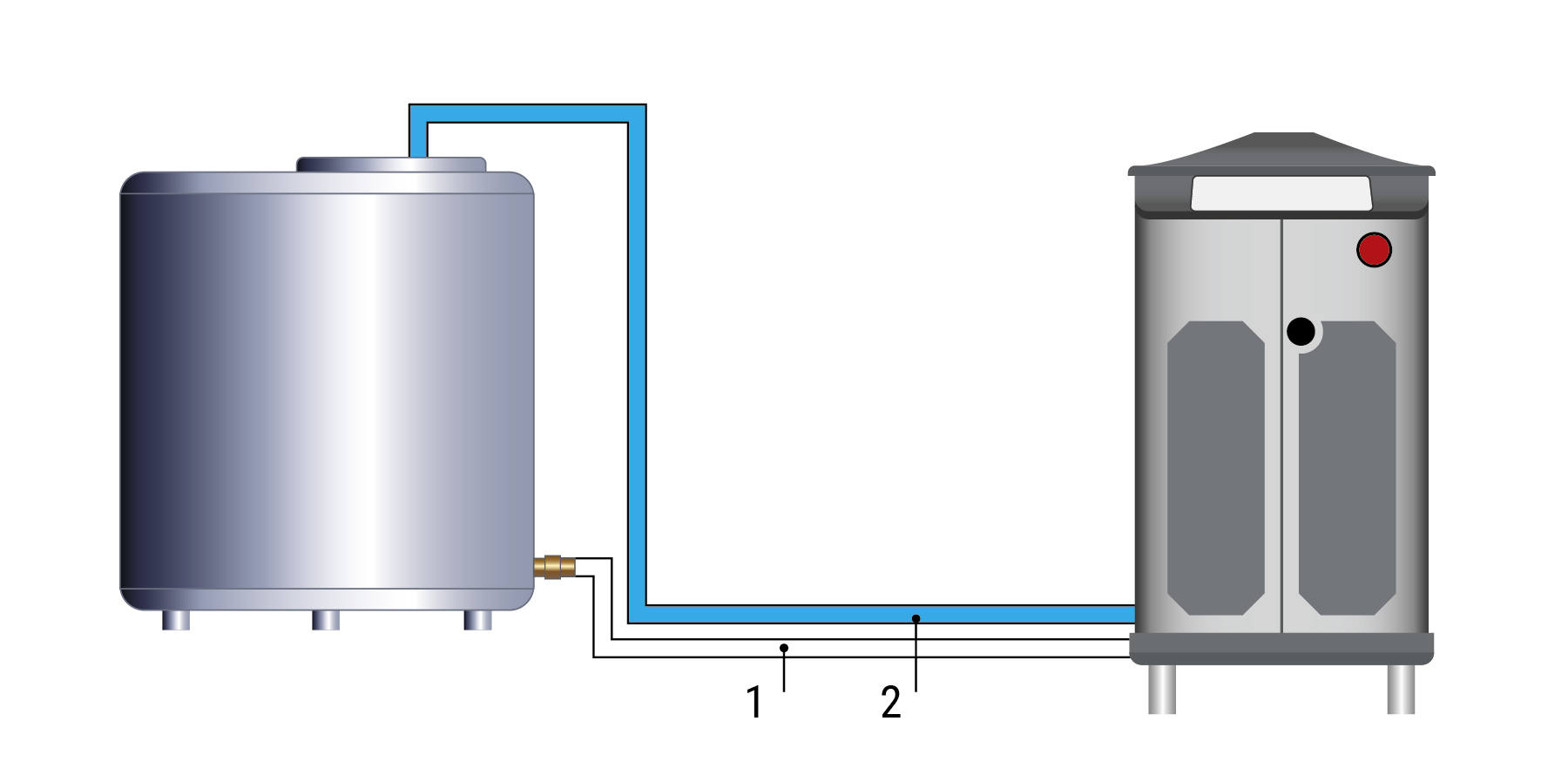

A simple milk tank on the calf feeder

A simple cooling tank directly on the CalfExpert needs to be filled manually. The downside of this system is that the actual fill level of the tank is unknown before the tank is filled. Residual amounts may have to be discarded. In addition, conventional milk tanks do not switch off refrigeration when the fill level is low, so any residual milk may freeze. These tanks are cleaned manually. The CalfExpert has a cleaning program for the supply line to the CalfExpert that needs to be started manually.

This is where the WholeMilkSmart option helps you, because you can see in the CalfGuide app how much milk is left in the tank and when it would be time to wash and then refill the tank.

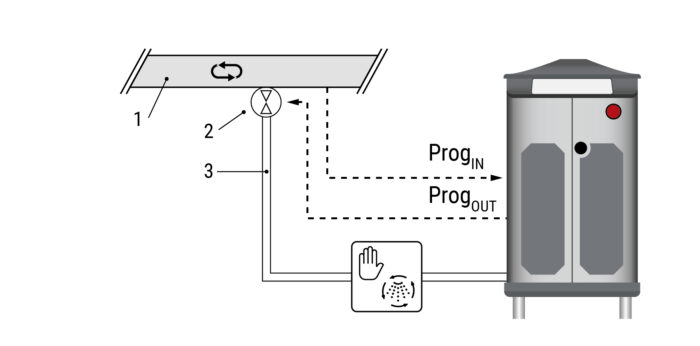

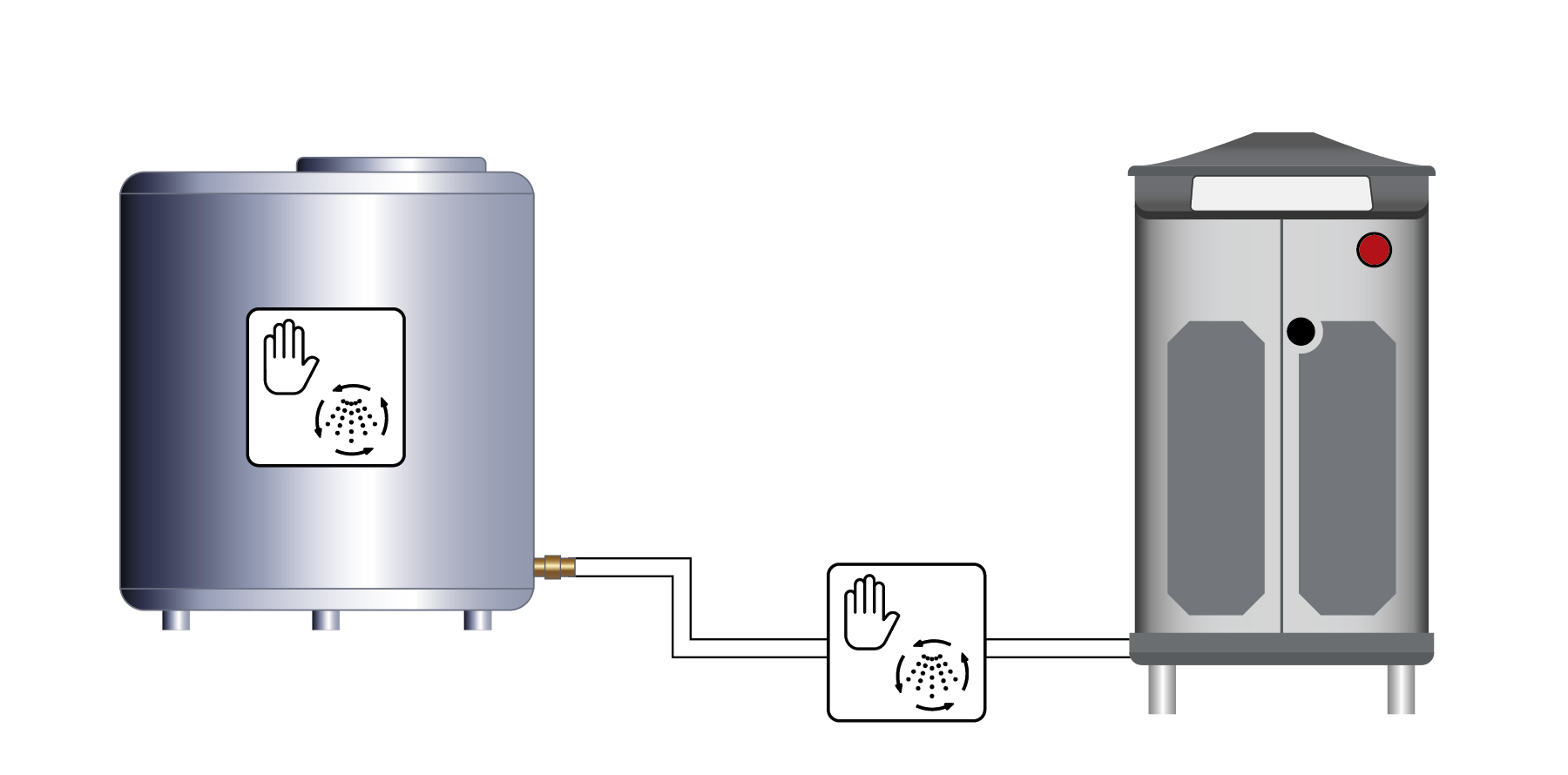

A simple milk tank with automatic supply line cleaning (SmartWash Undock)

The manual cleaning of the supply line described above is often forgotten or neglected due to time constraints. However, the supply line of the CalfExpert's whole milk supply is a particularly sensitive area from a hygiene point of view.

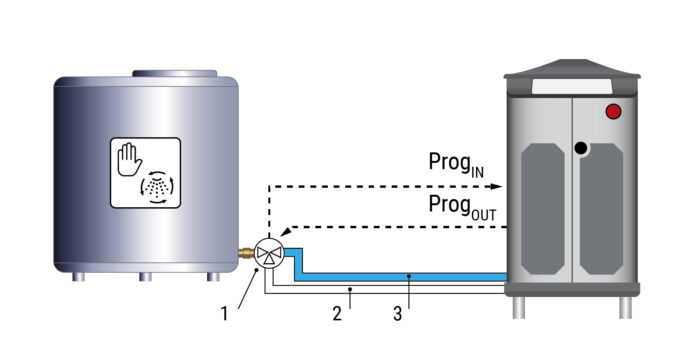

The SmartWash Undock solution provides a cleaning line all the way to the milk tank connection, where a switching valve is located that can be controlled via programmable

connections on the CalfExpert.

The CalfExpert disconnects from the milk tank by means of this switching valve and washes the supply hose during normal machine cleaning.

One milk tank with an automatic cleaning cycle (SmartWash)

Conventional tanks can be equipped with a cleaning pipe and a cleaning spray head in order to clean them optimally.

With SmartWash, the CalfExpert uses a cleaning line to clean the milk tank and the supply line. If the CalfExpert detects that the tank is empty, it will start its cleaning program, performing a combined cleaning cycle of the tank and the system. This results in the tank, supply hose, mixer, internal system and milk hoses to the hygiene stations being cleaned in a single "wash". The milk tank needs to have an automatic cooling shut-off so that it does not operate during cleaning. The CalfExpert offers an option of a programmable digital output for this purpose, which can send a corresponding signal to the milk tank (tank modification by an electrician is required).

Whole milk supply via ring line systems with central storage

Ring line systems are often used in larger operations that are equipped with several calf feeders and possibly even continuous pasteurisers for whole milk. The milk is transported from a central milk parlour with a storage tank to the CalfExpert feeders via supply lines.

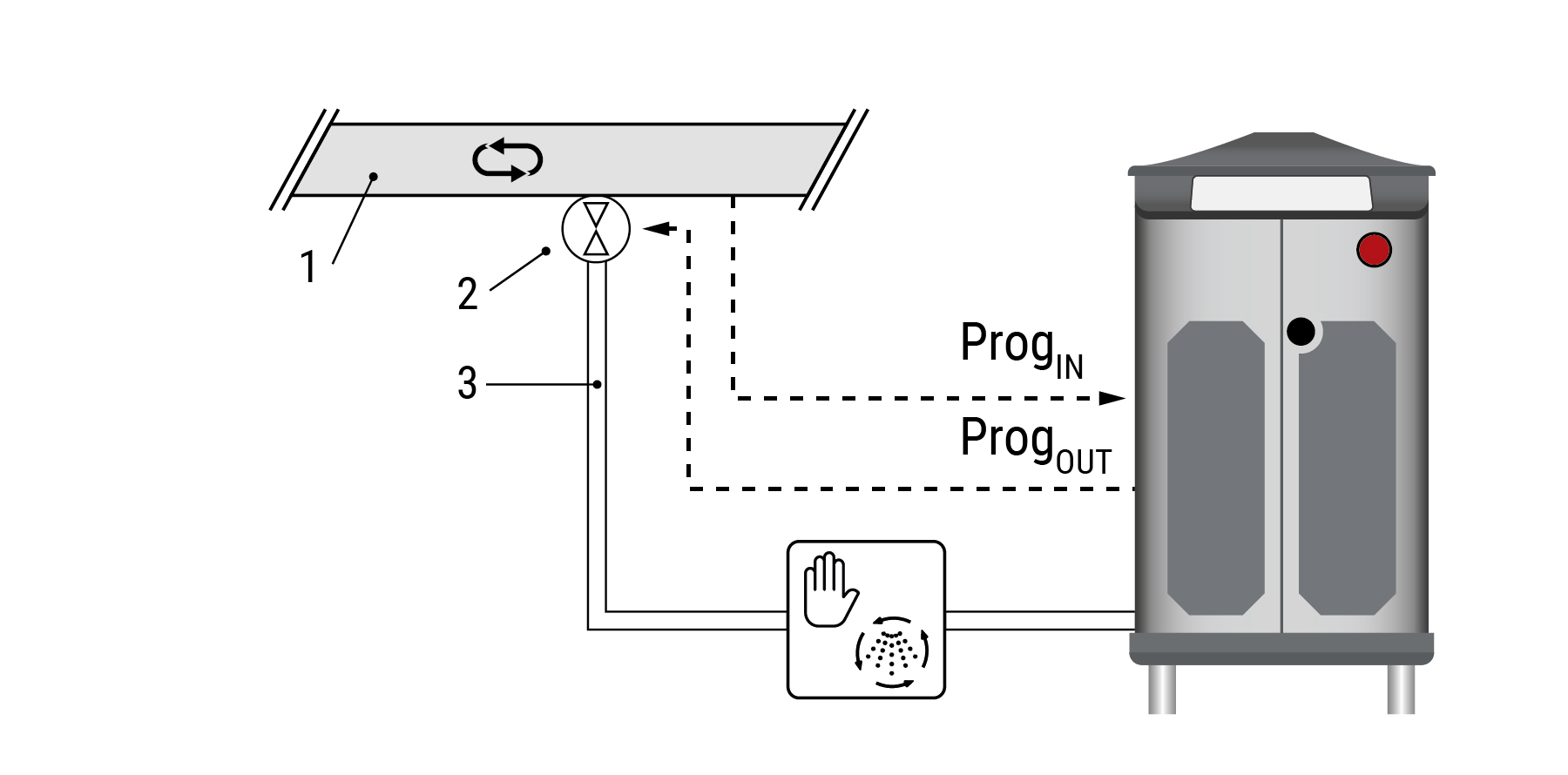

Ring line system with manual cleaning

Ring line systems need to be cleaned regularly. The CalfExpert may not feed when cleaning is in progress to prevent the calves from drinking the cleaning solution.

This requires communication between the ring line and the CalfExpert.

Programmable digital inputs and outputs on the CalfExpert:

The CalfExpert receives a 24V signal from the milk line cleaning control at the programmable digital input. This informs the feeder when the line is being cleaned and interrupts the feeding to start internal cleaning itself (if you wish). This avoids further interruptions to feeding. The increased pressure in the milk line can under certain circumstances open the valves in the CalfExpert and thus cause malfunctions. A fast-switching valve at the connection of the supply line to the calf feeder must prevent this. The programmable digital output allows the CalfExpert to open this valve when it needs milk for feeding. The drawback of this system is that the supply hose to the CalfExpert must be cleaned manually with the assistance of the CalfExpert.

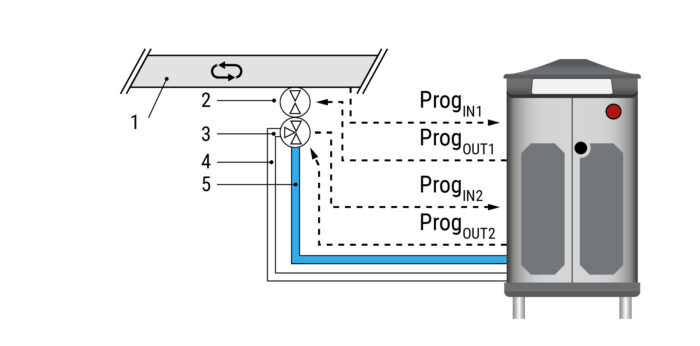

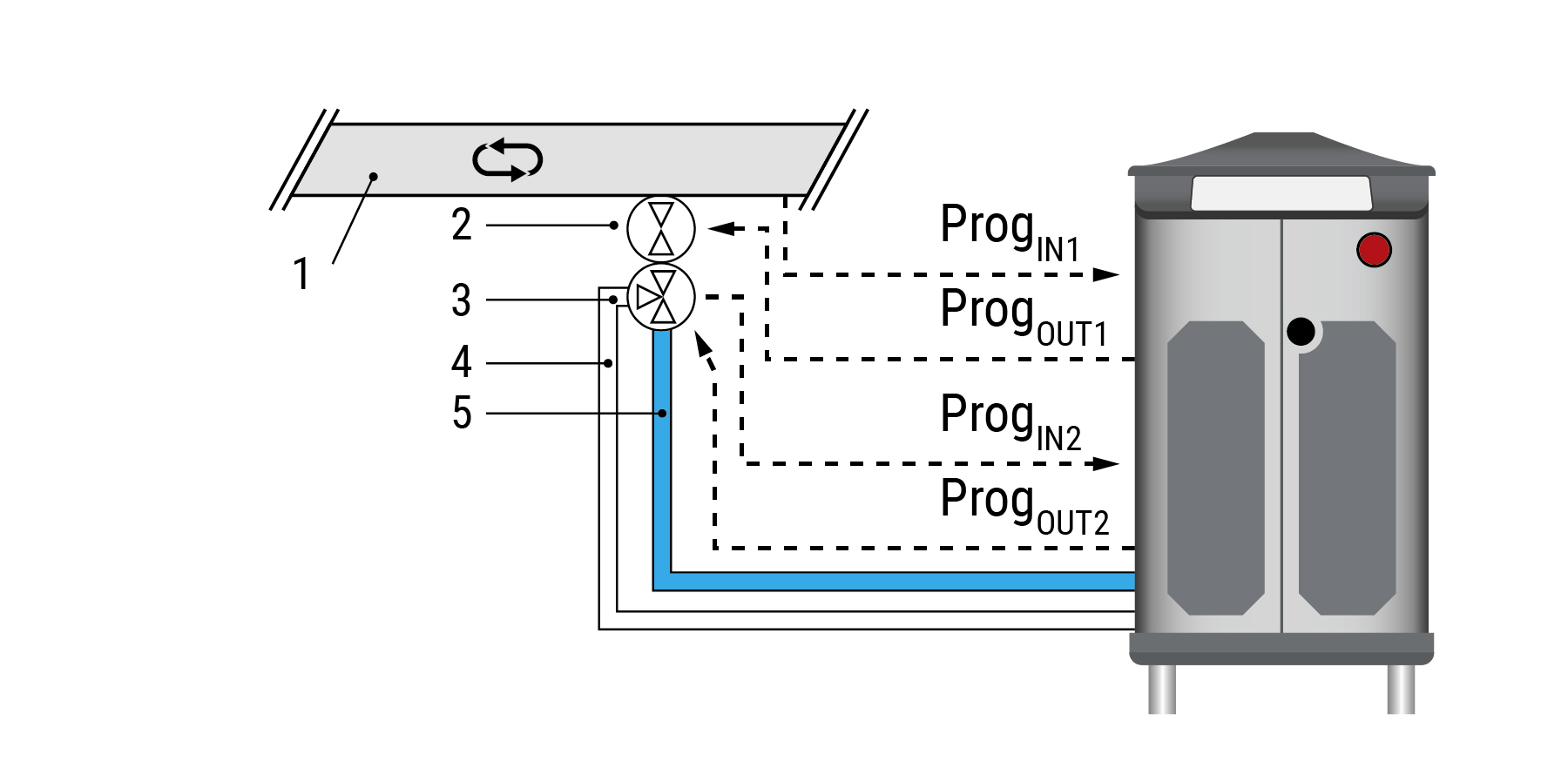

Ring line system with automatic Undock cleaning

Manual cleaning of the supply line is often forgotten or deliberately skipped in order to save time and give the calves more time to feed. However, this has

serious implications for hygiene and hence the health of the calves.

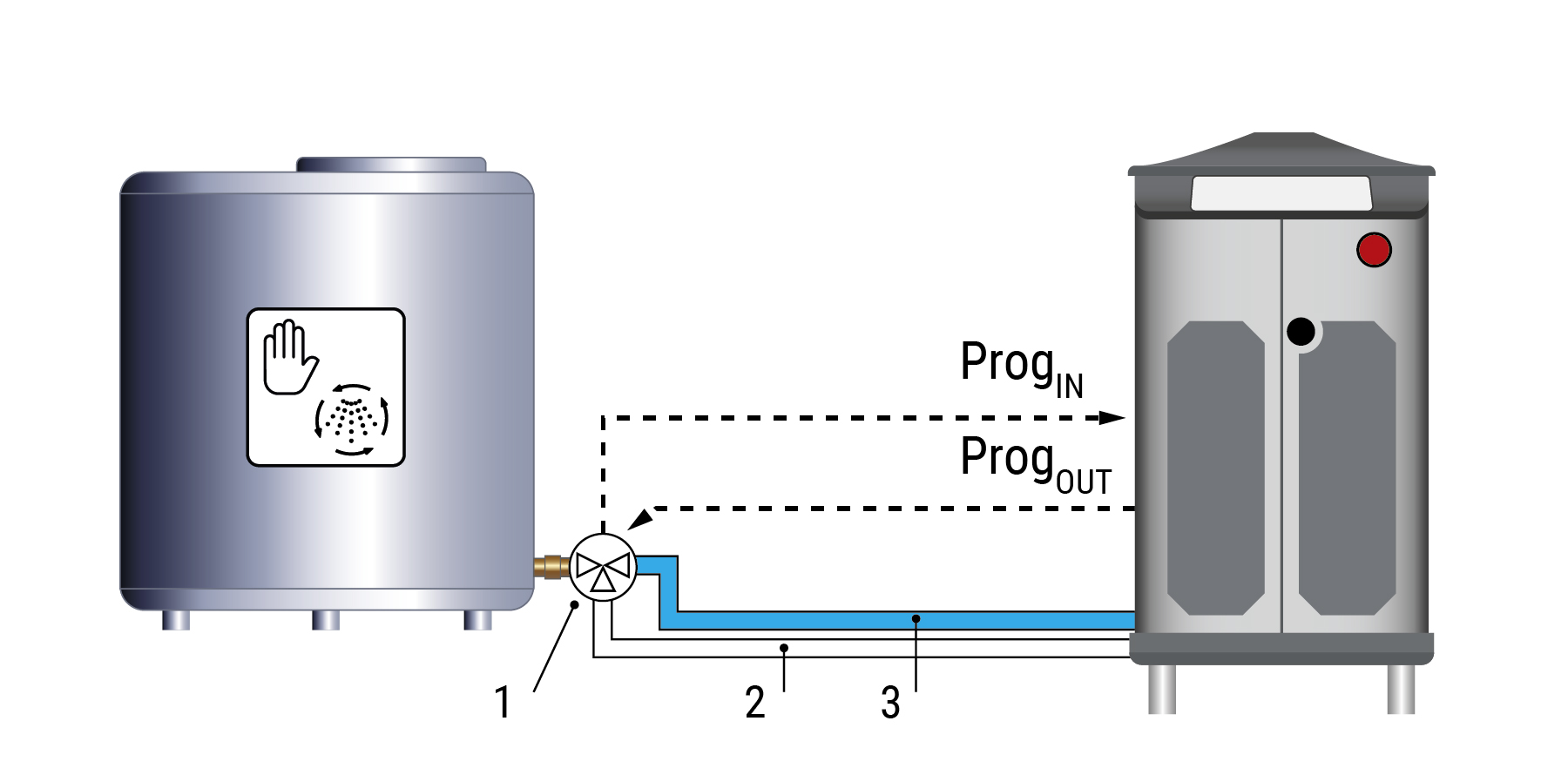

Programmable digital inputs and outputs on the CalfExpert with Undock cleaning:

As with the SmartWash Undock solution on the milk tank, this solution allows a cleaning line to be attached to the supply line connection valve. An additional switching valve provides the necessary cleaning circuit. It is controlled by digital inputs and outputs on the CalfExpert.

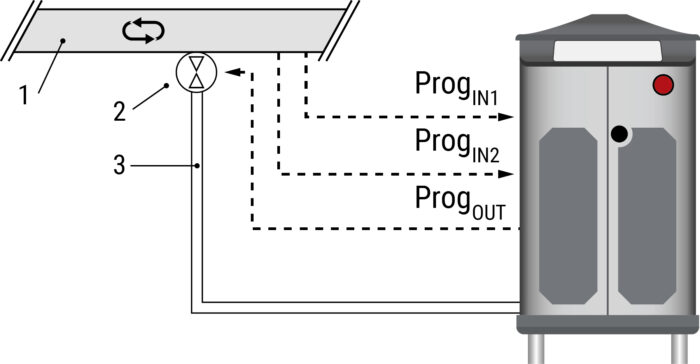

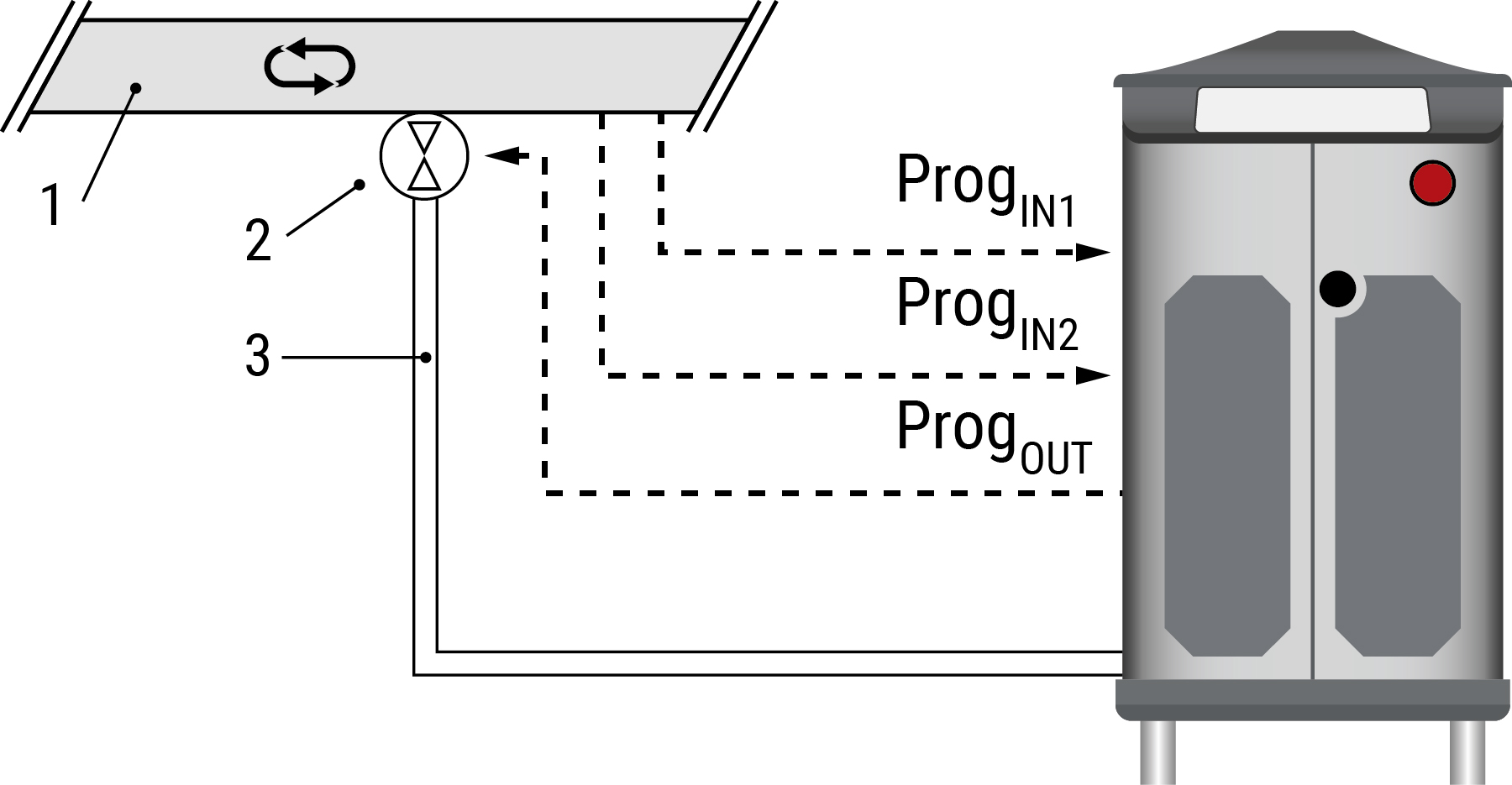

Ring line system with integrated cleaning

If the ring line cleaning system has a programmable control, the CalfExpert can also coordinate its own cleaning with the cleaning of the line.

Coded digital inputs and outputs on the CalfExpert:

By using two digital inputs, the ring line can send up to 4 different status signals (e.g. rinse, clean, milk present, empty). The CalfExpert can then join the cleaning process and takes rinsing and cleaning fluid from the ring line for its own cleaning. This also cleans the supply hose automatically.

1=ring line, 2=supply hose, 3=cleaning line

1=ring line, 2=supply hose, 3=cleaning line

1=supply hose, 2=cleaning line

1=supply hose, 2=cleaning line

1=ring line, 2=fast switching valve, 3=supply line

1=ring line, 2=fast switching valve, 3=supply line

1=ring line, 2=fast-switching valve, 3=switching valve, 4=supply line, 5=cleaning line

1=ring line, 2=fast-switching valve, 3=switching valve, 4=supply line, 5=cleaning line

1=ring line, 2=fast switching valve, 3=supply line

1=ring line, 2=fast switching valve, 3=supply line