Successful calf rearing with standardised operating procedures (SOPs)

30. Oktober 2025 — Calf Feeding, Calf Husbandry, Calf management, Practice reportEnsure the health of your calves right from the start, optimise work processes and save time and resources at the same time – all with one simple but effective method. When it comes to animal husbandry, it is often the small details that make the difference between average and outstanding breeding performance. However, how can you ensure that all employees consistently work to the highest standards? The answer lies in clearly formulated operating procedures – known as SOPs. They are the invisible backbone of successful calf rearing and can make a vital difference to the efficiency of a farm.

What are SOPs and why are they important?

SOPs are standardised procedures that ensure that all activities are carried out in line with defined processes. They are a tool for ensuring consistency and quality in work processes while minimising errors. A workflow is broken down into small building blocks and presented in a way that is easy for every user to understand. When employee responsibilities change or new employees are being trained, SOPs are a great help in enabling work processes to be carried out independently.

SOPs in calf rearing can cover a wide range of different processes: from feeding and health checks to hygiene and technical maintenance. Systematic application of these SOPs ensures that calves receive the best possible care every day.

Practical example: Rohwer farm – successful implementation of SOPs in calf rearing

The Rohwer dairy farm in Aukrug has successfully introduced SOPs for calf rearing. With 230 dairy cows, the farm relies on the support of part-time workers who are actually active in other occupational fields and have no agricultural background. This poses the challenge that everyday tasks are not always performed to the same standard and in the same way. The farm introduced SOPs to provide support in this area and make work processes more efficient. Detailed instructions have been drawn up for all important work steps, particularly in the area of calf rearing and feeding:

Initial feeding with colostrum after birth

At birth, the calf's initial feeding with colostrum follows a clear procedure. Colostrum is thawed and fed from a feeding bottle as standard for every calving outside of milking times. The Brix values of the colostrum are measured, documented and it is organised in the freezer according to quality grades.

There are precise specifications as to which calf (male, female, difficult birth) should receive which quality of colostrum. This SOP also defines exactly how thawing and feeding are to be carried out. An important point for this SOP was to specify how long the colostrum needs to thaw. This ensured that drenching was not carried out too late or forgotten.

Particular attention needs to be paid in this area to ensuring that SOPs are assigned a clear objective. Since calving involves many important steps – such as providing initial care for the cow – it is advisable to define sub-areas for which small, specific SOPs can be formulated. This allows employees to work through small tasks one after the other, ensuring that no steps are forgotten.

Weighing at birth

Newborn calves are weighed when they are transported to the calf area. WeightControl not only documents the birth weight, but also records other information about the calf, such as breed, date of birth and calving progress, as well as the time and amount of colostrum given.

The SOP describes how to correctly place the calf on the scales, how to assign the weight to the corresponding live ear tag and how to record details about the calf. It is particularly important to record the initial weight correctly, as subsequent weighings will be used to calculate individual daily weight gains.

Preparing calf feed

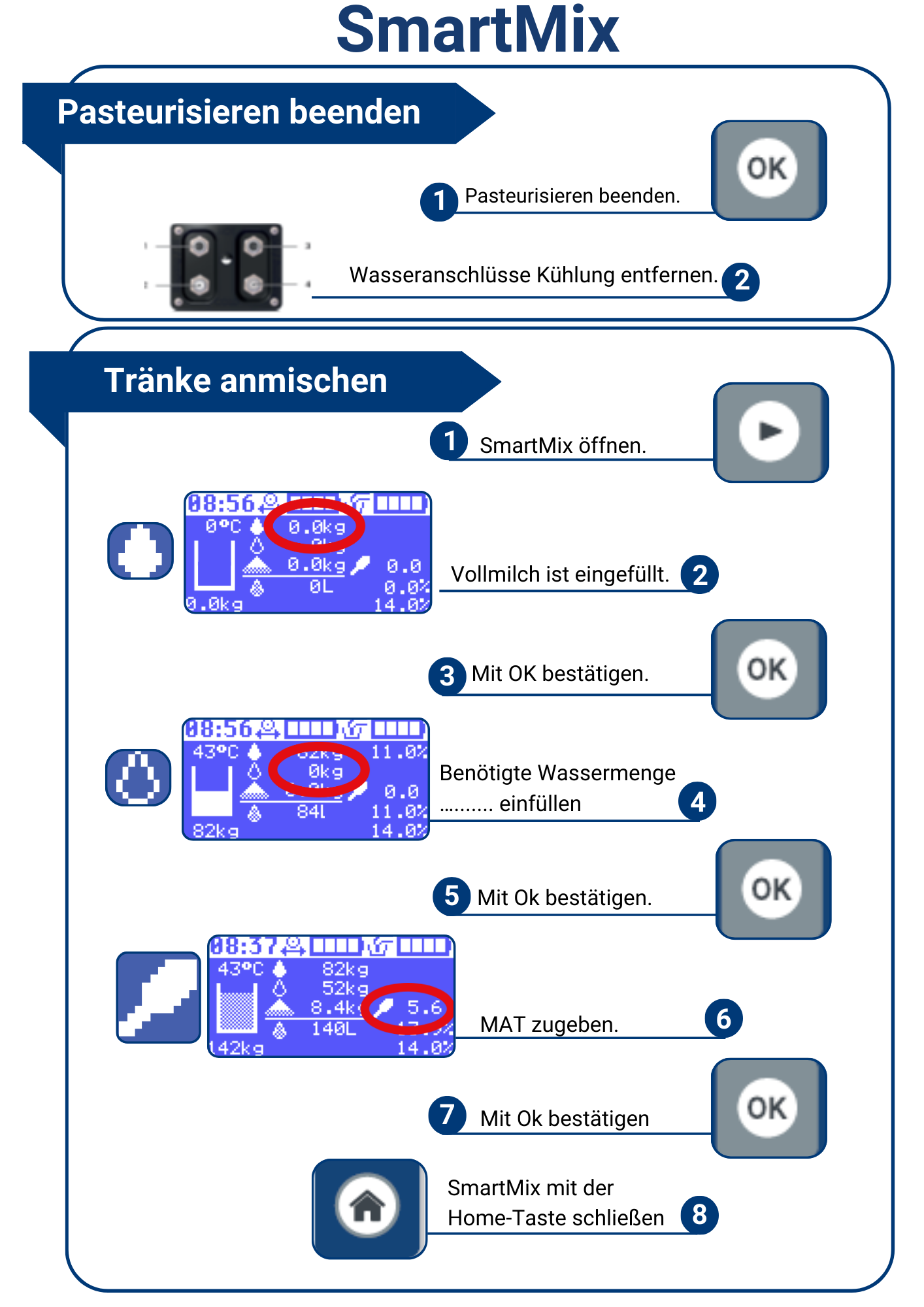

The farm considers the SOP for preparing calf feed to be of utmost importance in order to ensure consistent formulations. Special attention needs to be paid to preparing the calf feed correctly, as the farm feeds a mixture of pasteurised whole milk and milk replacer. Employees have access to an SOP that describes the exact mixing procedure to ensure that the composition of the feed is always identical. Holm & Laue's MilkTaxi with the ‘SmartMix’ function is used for mixing to achieve the best possible results.

The SOP guides the user through the individual steps so that the ingredients are added in the correct order and the MilkTaxi can accurately measure the quantities of whole milk and water. Since a consistent dry matter content is particularly important, SmartMix calculates the enrichment of whole milk (here: 11% DM set for whole milk) and the exact composition of the ingredients to achieve the desired dry matter content of 14%.

The whole milk portion is also acidified, and the addition of the powder is described in detail, including the dosage and method of mixing. This SOP describes each step in detail using the corresponding button icons on the MilkTaxi. This is particularly helpful when training new employees and when tasks change at short notice. This provides employees with excellent support when they have to prepare the feed on their own for the first time, enabling them to work much more independently.

Daily tasks in the calf area

The calf area features an overview of the igloo system barn, showing which tasks need to be completed each day. This means that every employee can see at a glance what tasks need to be completed and can check at the end of their shift to make sure that nothing has been forgotten.

The diagram also shows directly how the stable should ideally be vacated. This eliminates the need for inspection rounds, and no one has to worry about unfinished work anymore. The nesting score is also displayed as an additional aid, primarily to provide young calves with sufficient protection in unfavourable weather conditions.

Cleaning and disinfection of individual igloos

The igloos are also cleaned and disinfected according to a defined process in order to minimise the risk of infection. This includes instructions on setting up the workplace, using suitable cleaning agents, exposure times and cleaning with a high-pressure cleaner. It has proved particularly important in this SOP to point out important areas that are easily overlooked during cleaning.

For example, it is important to make sure that the bedding door is open during washing, that the outlet grille is folded up and that the igloo is also cleaned from below. Disinfection is also explained in detail, including precise descriptions of dosages and exposure times.

Benefits of using SOPs in calf rearing

Standardised workflows ensure consistent quality across the entire farm. Mistakes can be avoided, especially during critical stages of life, such as when colostrum is administered. Clear instructions prevent misunderstandings between employees and ensure optimum calf husbandry. In addition, work processes are optimised while saving time and resources. New employees can be trained quickly, and the clear documentation of processes also provides an excellent reference work.

Conclusion

The farm was able to make work in the calf area much more efficient as a result of introducing the SOPs. This ensures that the calves receive optimum care at all times. What is more, employees' independence and self-confidence have been significantly enhanced.